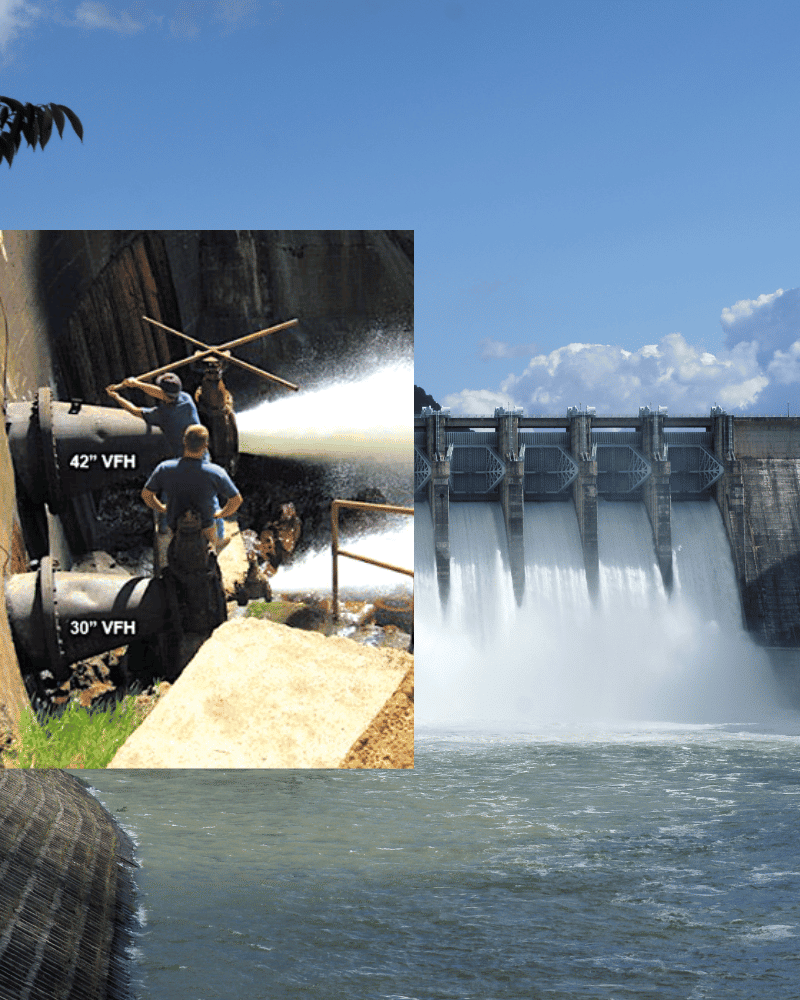

The VFH Turbine™ consists of the complete mechanical, electrical, and process control assembly for “smaller” and “medium” flow requirements. Based on the example photo shown, the 42″ diameter inlet and 30″ diameter inlet can produce up to 650 kW per unit for a Reservoir site. The two existing pipes & flanges coming from the dam will seamlessly match those of our butterfly valve and VFH Turbine™ flanges.

The VFH system has been designed to stop the turbine from spinning and allows the flushing process to move more silt and sediment without damaging the turbine or generator. Reservoir flushing helps remove deposited sediments from the reservoir to retrieve the reservoir storage capacity and help flood control.

San Juan, Puerto Rico

Copyright © 2024 VFH Turbine. All Rights Reserved.